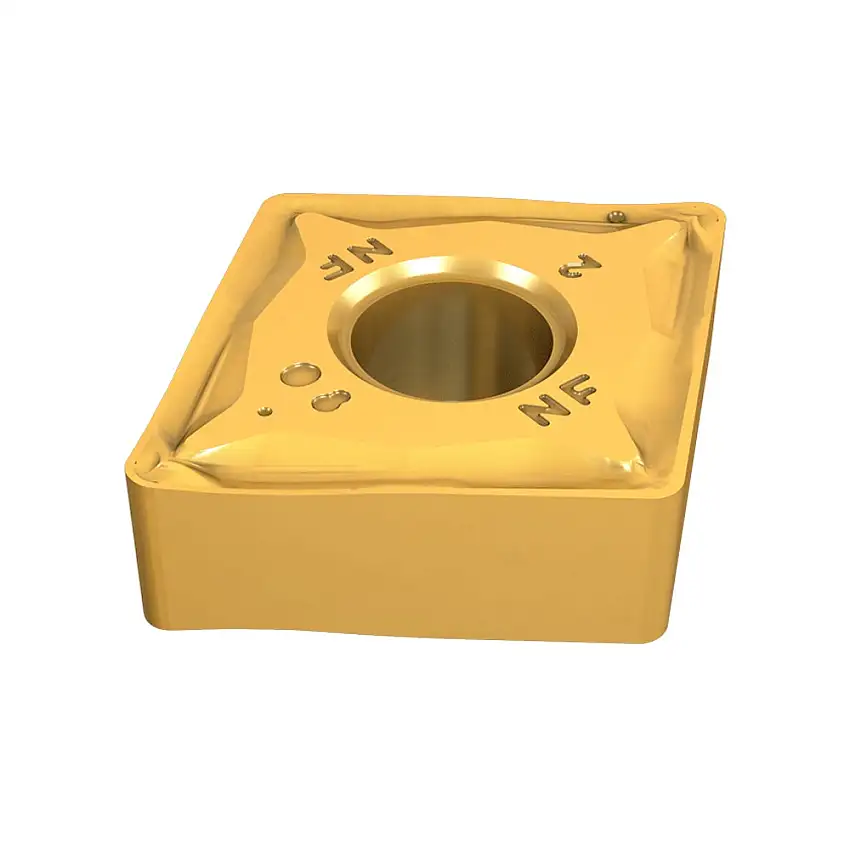

| Insert Style: | CNMG |

|---|---|

| Corner Radius (mm): | 0.4 |

| Chipbreaker: | NF |

| Grade: | IC9250 |

| Material Application: | Steels; Stainless Steels |

| Maximum Depth of Cut (ap/mm): | 3.5 |

| Maximum Turning Feed (mm/rev): | 0.25 |

| Minimum Depth of Cut (ap/mm): | 0.4 |

| Minimum Turning Feed (mm/rev): | 0.08 |

| Application: | Finishing |

| ISO Code: | CNMG120404 |

| Number of Edges: | 4 |

| Manufacturer Part Number: | 5507634 |

| Brand: | Iscar |

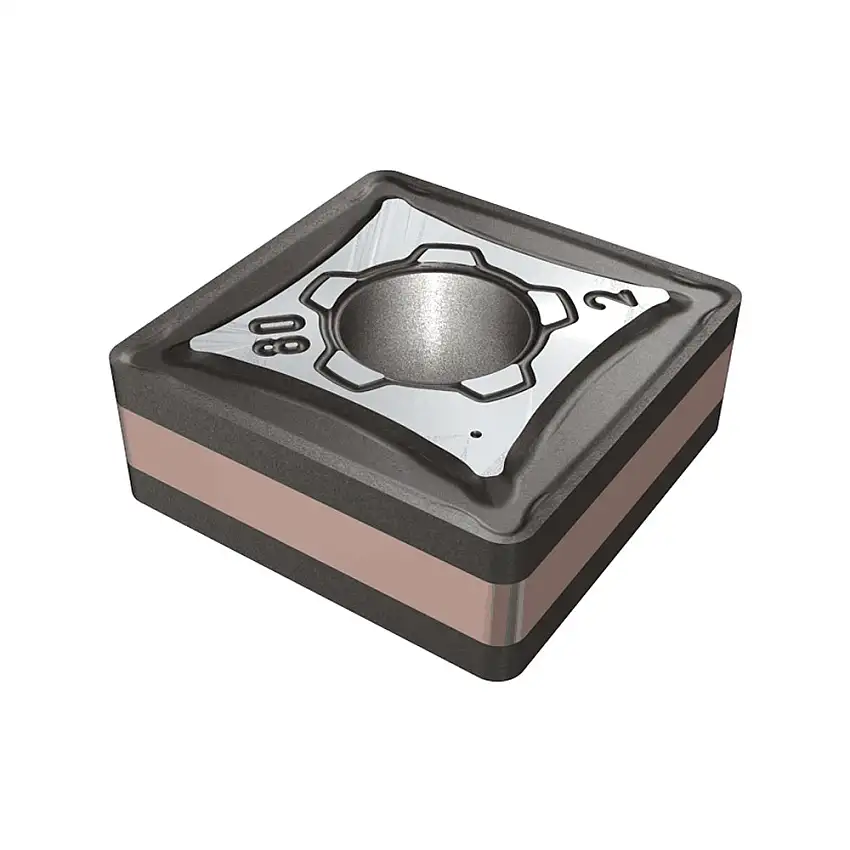

ISO-Turn – Double sided 80° negative rhombic turning insert with 4 cutting edges – A pressed insert for facing and straight turning. For semi-finishing and finishing applications. Low cutting forces due to very sharp edge and positive rake. Grade IC9250 (CVD TiCN+alpha Al203+TiN coating) – A tough substrate with a cobalt enriched layer combined with a thick CVD coating. Recommended for general use machining ofsteel in a wide range of conditions, featuring high toughness and wear resistance.

Features & Benefits:

Iscar’s Iso-Turn – This is a wide range of Iso turning inserts that come in a variety of shapes, sizes, nose radius, chip breakers and grades. – Iso means these inserts can fit directly into any manufactures ISO external turning and internal holders. – There’s an insert configuration to machine any shape profile in all workpiece materials. Positive and negative inserts are available within this range.

Reviews

There are no reviews yet.