|

Brand |

Iscar |

|

Chipbreaker |

J |

|

Compatible Materials |

High-Temperature Alloys Stainless Steel Steel |

|

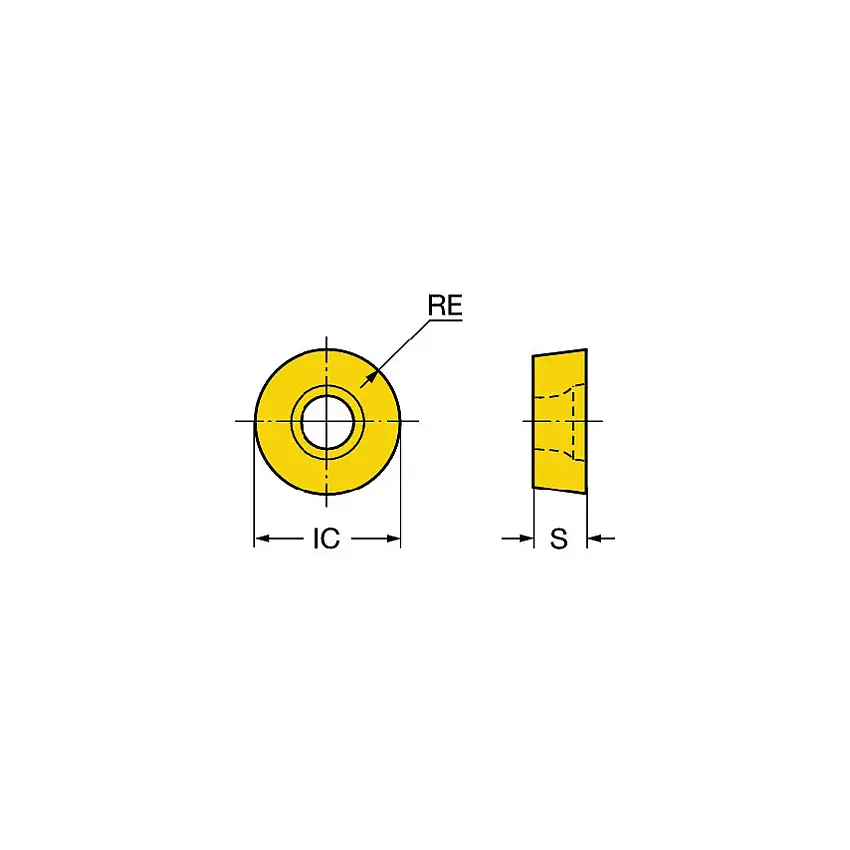

Corner Radius |

0.24mm |

|

Cutting Application |

Grooving Parting |

|

Cutting Direction |

Neutral |

|

Cutting Location |

External |

|

ECLASS Code |

21010901 |

|

Finish/Coating |

Multilayer TiAlN/TiN |

|

Grooving Width |

4mm |

|

Insert Holding Type |

Self Grip |

|

Insert Style |

TAG |

|

ISO Category Grade |

M P |

|

ISO Designation |

TAG N4J |

|

Manufacturer Grade |

IC830 |

|

Material |

Carbide |

|

MFR Part No. |

6011389 |

|

Radius Type |

Corner Radius |

|

Series |

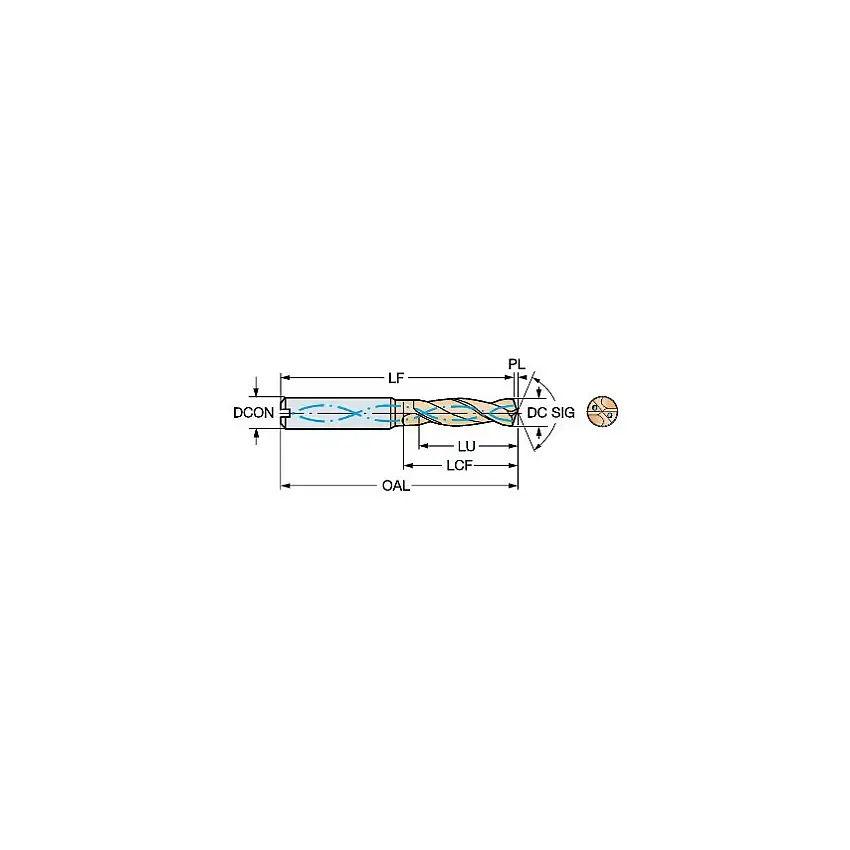

Tang-Grip |

|

UNSPSC Code |

31162802 |

TAG N-J/JS/JT : First choice for soft materials, alloy steel and austenitic stainless steel. Parting of tubes, small diameters and thin-walled parts. Cutting edge with positive rake used at low-to-medium feeds. The JS-type has sharp corners. 70% more productivity, tangentially clamped, single-ended parting system

ISCAR’s new, single-ended insert for parting with an improved clamping method.

Features and Benefits

- Very rigid clamping in a tangentially oriented pocket

- Enables machining at very high feed rates and provides excellent straightness and surface finish

- Recommended for parting large diameter parts and for interrupted cuts

- Offers a free, unobstructed chip flow, since there is no upper jaw

- The combination of tangential clamping and free chip flow results in improved tool and insert lifetime

- Provides a solution to the problem of inserts being pulled out during retraction

Specifications

- Grade: IC830

- A ‘SUMO TEC’ AlTiN+TiN PVD coated grade

- ISO Range – P/M/K: (P20-P40)(M25-M35)

- ISO Range – H/S/N: (S15-S30)

- Grade or Coating Type: PVD

- Coating Layers: AlTiN+TiN

Typical Applications

- Parting

- Stainless steels

- Steel

Reviews

There are no reviews yet.